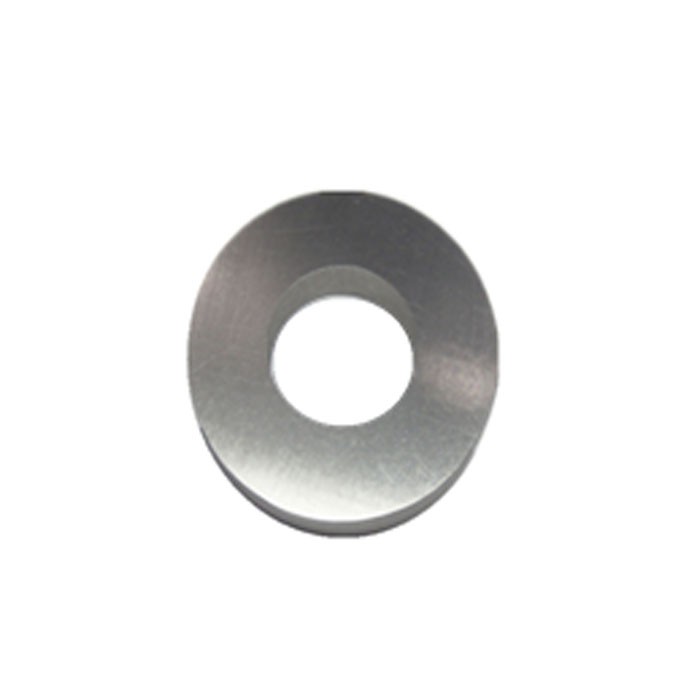

Direct Current Motor Magnet

- HBHAISHU

- Zhejiang

- 15-30days

- 50 Ton/Tons per Month

Direct current motor magnet is high precison.It has excellent magnetic properties, high inherent coercivity, stable magnetic properties and good consistency in mass production.Due to the selected high quality raw materials,Direct current motor magnet has stable performance,such as good magnetic force and temperature resistance.Besides,the surface is clean and beautiful, without blisters, cracking, peeling and other phenomenon.

Direct Current Motor Magnet

1.Description:

Arc magnets are mainly used in permanent magnet direct current motors,so it is also known as direct current motor magnet. permanent magnet motors generate a constant magnetic potential source from permanent magnet materials,while electromagnetic motors generate a magnetic potential source through the excitation coil.Dc motor magnet can make the motor simple structure, light weight, small volume, reliable use, easy maintenance, low consumption of copper and low energy consumption.

Customers should choose the appropriate magnet grade according to its working temperature. If the working temperature is higher than the bearing temperature of the magnet brand, the magnet will slowly demagnetize until there is no magnetism.Please confirm the working temperature and the brand number suitable for your own use before ordering.

If the magnet is used in a sealed state, it can be considered to choose the magnet without electroplating or white zinc plating on the surface, which can save costs. If the magnet is exposed to moist air, especially in the salt spray state, it is recommended to consider the magnet with nickel plating on the surface.Magnets should be stored in a dry, constant temperature environment.Magnet should be separated and wrapped in plastic, wood, cardboard, foam, etc.Stay away from iron and easily magnetized objects, such as monitors, bank CARDS, computers, televisions, mobile phones, etc.

2.Grade:35SH-42SH,35UH-40UH

3.Physical Properties of Sintered NdFeB Magnets

Br temperature coefficient (%/℃) | -0.09-0.13 |

Hcj temperature coefficient (%/℃) | -0.04-0.80 |

Curie point(℃) | 310-340 |

Specific resistance(μΩ·cm) | 150-200 |

Thermal conductivity(W/(m·℃)) | 6-10 |

Specific heat(J/(kg·℃)) | 450-600 |

Expansion coefficient(10/℃) | 5-8(Magnetizing direction) |

-0.1--0.4(Pressing direction) | |

Bending strength(MPa) | 200-300 |

Compressive strength(Mpa) | 950-1050 |

Tensile strength(Mpa) | 65-95 |

Vickers hardness | 500-650 |

4.Packaging & Delivery

Packaging Details:Standard export seaworthy package.Cartons with foam protected, or according to customer's request.

Delivery: EMS, DHL, TNT, UPS, container shipping.

FAQ:

1. Do you provide free samples?

If we have the products in stock, the samples is free. But customer should bear all the shipping costs. Meanwhile, custom-made sample is available.

2. What's the minimum quantity customer can order?

We accept small order.

3.What is the lead time?

Usually sample lead time is 5-10 days after payment has been confirmed.

Normal order is 15-30days,it depends on customers' quantity

4. What's our payment terms?

We can accept T/T and LC payment terms, it also depending on delivery and total amount.

5.How do you guarantee the quality?

We will track and monitor whole production process, as well as test to each process.Besides,we are willing to accept customer testing.

6. What's our working time?

We will give you reply through email/phone Online chat tool within 24 hours.