FeNiCo Glass Sealing Alloys

- SG

- Jiangsu

- 15-30days

- 1200 Kilogram/Kilograms per Month

Due to the expansion characteristics of FeNiCo Glass Sealing Alloys,they have became the most popular of the controlled expansion alloys for hermetic sealing applications. The main applications is as magnetic shunt compensatory element in the electromagnetic loop and the permanent magnetic loop.

FeNiCo Glass Sealing Alloys

1.Alloy:4J29、4J44

2.Dimensions:

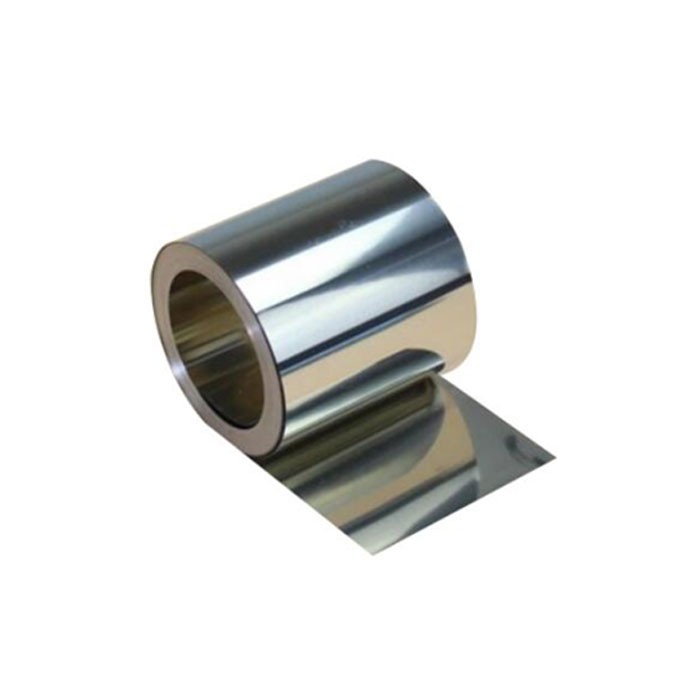

Cold rolled strip:(0.01mm-3mm)×(1mm~300mm)

Hot rolled plate: (2.5mm-20mm)×(100mm-300mm)

Cold drawn wires: Φ0.025~2.0 × L

3.Characteristics:FeNiCo Glass Sealing Alloy is a kind of nickel Base Alloy,consisting of nickel,cobalt and iron.Nickel.It has the characteristics of high magnetic conductibility ,high resistance,high hardness,high saturation induction.FeNiCo Glass Sealing Alloys have certain linear expansion coefficient under -60℃~+40O℃. They can seal to hard glasses firmly.

4.Applications:FeNiCo Glass Sealing Alloys are fit for manufacturing electro-vacuum components, such as oscillation tube, ignition rectifiers, transistors, pipe-closers and outer casings of relay.

5.Chemical compositions(%)

Alloy | Ni | Co | Fe |

4J29 | 28.5~29.5 | 16.8~17.8 | rest |

4J44 | 34.2~35.2 | 8.50~9.50 | rest |

Average linear expansion coefficients&tensile strengths of strips

Alloy | Heat treatment | Average linear expansion coefficients a/10-6·K-1 | Condition(symbol) | Tensile strength σ b/ MPa | ||

20~300℃ | 20~400℃ | 20~450℃ | ||||

4J29 | Heating to(900±20)℃ in hydrogen holding for one hour ,reheating to(1100±20)℃ ,holding for 15min ,cooling at a rate less than5℃ per minutes to 200℃,then air cooling. | - | 4.6~5.2 | 5.1~5.5 | Soft(R) | <570 |

1/4 hard(1/4) | 520~630 | |||||

4J44 | 4.3~5.1 | 4.6~5.2 | - | 1/2 hard(1/2) | 590~700 | |

3/4 hard(3/4) | 600~700 | |||||

hard | >700 | |||||

6.Packaging & Delivery

Packaging Details:Standard export seaworthy package. Wooden case of customized.

Delivery: EMS, DHL, TNT, UPS, container shipping.

FAQ:

1. Do you provide free samples?

Yes, we could offer the sample for free charge.But clients should bear all the shipping costs. Meanwhile, custom-made sample is available.

2.How do you guarantee the quality?

We will track and monitor whole production process, as well as test to each process.Besides,we are willing to accept customer testing.

3. What's the minimum quantity customer can order?

If we have the size in stock, we can provide any quantity.

If we do not have in stock,generally,the minimum quantity depends on different products.Please contact with us to confirm.

4. What's our payment terms?

We can accept T/T and LC payment terms, it also depending on delivery and total amount.

5.What is the lead time?

Usually sample lead time is 5-7days after payment has been confirmed.

Normal order is 15-30days,it depends on customers' quantity.

6. What's our working time?

We will give you reply through email/phone Online chat tool within 24 hours.

Important Notice

All the information above is only for reference. We can adjust chemical composition, physical and mechanical properties according to customers’ requirements. The specific details need to consult the sales staff.