Inconel 718

- SG

- Jiangsu

- 15-30days

- 1200 Kilogram/Kilograms per Month

The alloy of Inconel 718 has good tensile, fatigue, creep, and rupture strength. It is easy to machine according the requirement of usage.

Inconel 718

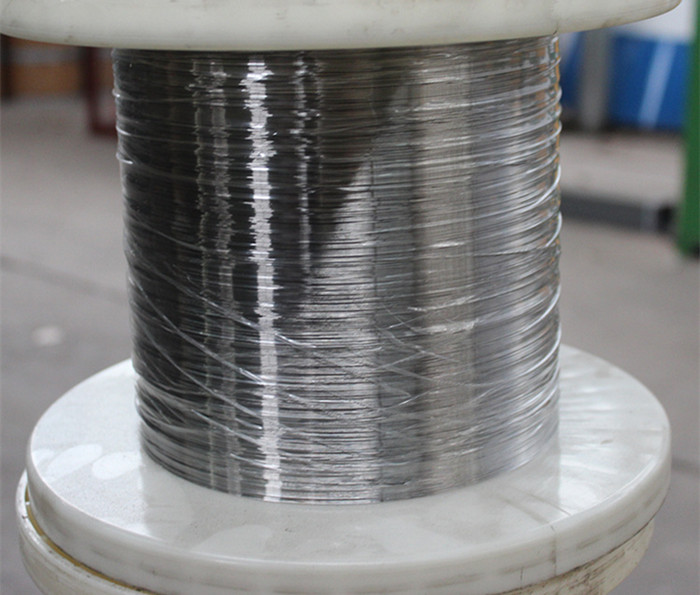

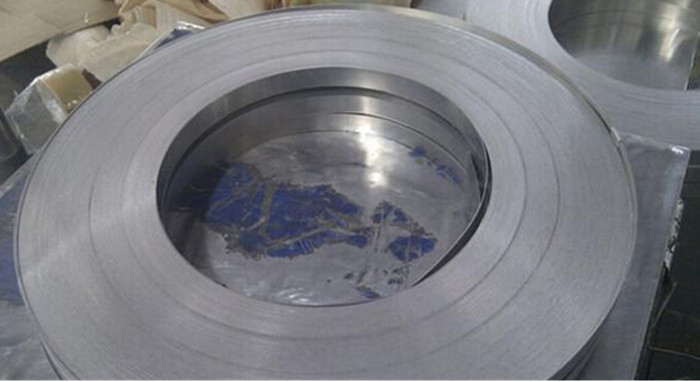

1.Alloy:Inconel718

2.Dimention:Generally,standard size is in stock.Or according clients’ order.

3.Properties:Inconel 718 is Nickel Chromium,solid solution strengthened alloy with good resistance to oxidation and corrosion at high temperatures.Inconel Alloy is almost completely resistant to mild environments such as the atmosphere, fresh water and seawater, neutral salts, and alkaline media.

4.Application: metal parts for aircraft and rocket,fasteners and instrumentation parts.

5.Chemical compositions(%)

% | Ni | Cr | Fe | C | Mn | Si | Cu | P | S | Al |

Inconel718 | 50-55 | 17-21 | rest | 0.08 | 0.35 | 0.35 | 0.3 | - | 0.01 | 0.2-0.8 |

6.Packaging & Delivery

Packaging Details:Standard export seaworthy package. Wooden case of customized.

Delivery: EMS, DHL, TNT, UPS, container shipping.

FAQ:

1.How do you guarantee the quality?

We will track and monitor whole production process, as well as test to each process.Besides,we are willing to accept customer testing.

2. Do you provide free samples?

Yes, we could offer the sample for free charge.But clients should bear all the shipping costs. Meanwhile, custom-made sample is available.

3. What's the minimum quantity customer can order?

If we have the size in stock, we can provide any quantity.

If we do not have in stock,generally,the minimum quantity depends on different products.Please contact with us to confirm.

4.What is the lead time?

Usually sample lead time is 5-7days after payment has been confirmed.

Normal order is 15-30days,it depends on customers' quantity.

5. What's our payment terms?

We can accept T/T and LC payment terms, it also depending on delivery and total amount.

6. What's our working time?

We will give you reply through email/phone Online chat tool within 24 hours. No matter working day or holidays.

Important Notice

All the information above is only for reference. We can adjust chemical composition, physical and mechanical properties according to customers’ requirements. The specific details need to consult the sales staff.